Pickling

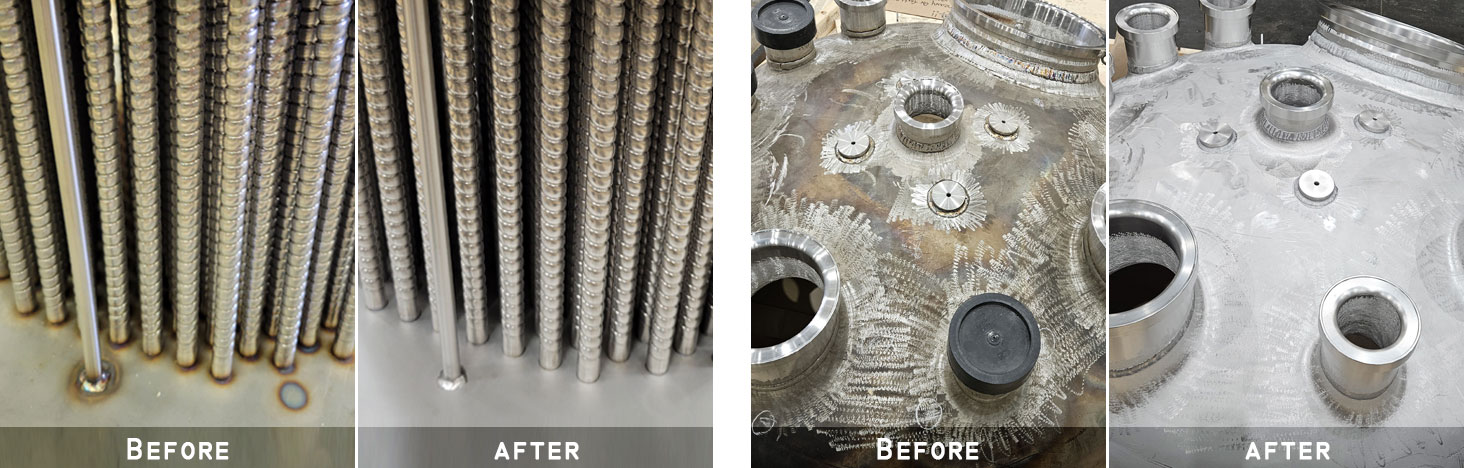

Pickling or chemical descaling is but one of several pretreatment steps available for preparing an article for further processing such as passivation or electropolishing, or to perform a superior cleaning operation on welded structures.

Pickling is the chemical cleaning of metallic surfaces in order to remove impurities, stains or scale with an acidic solution.

Pickling Capabilities

We have two methods of stainless steel pickling, each with its own advantages and applications.

- Acid Pickling: This is the traditional method of pickling stainless steel, where the material is immersed in an acid solution consisting of nitric and hydrofluoric acids to remove the scale and underlying chromium depleted layers to restore the corrosion resistance of stainless steel. The acid dissolves the surface contaminants, and produces a clean stainless steel surface. Acid pickling is suitable for most stainless steel grades.

- Pickling Paste: Pickling paste contains a mixture of acids and inhibitors. It is applied directly to the surface of the stainless steel, to dissolve the contaminants. Pickling paste is particularly useful for localized pickling. For these applications, pickling pastes might be used to pickle specific areas of welds or to touch up small spots that need deeper pickling. The paste may also be used to pickle parts too large to submerge into the acid baths or for assemblies that might have non-stainless components.

The choice of pickling method depends on many factors, including the type of stainless steel, the size and shape of the parts, and the specific requirements of the application.

Our facility has a dedicated area for safely pickling large parts. This enables us to process any part that can be transported to our facility. Allegheny Surface Technology (AST) can pickle passivate inside or outside a tank, depending on the size of your product.

Why Choose Our Metal Pickling Company?

- ✓ We are a leader in Pickling services

- ✓ ASTM A380

- ✓ Shop & field services available

- ✓ Single parts to bulk parts

- ✓ Large scale solutions

- ✓ Environmentally responsible, Hexavalent Chromium Free

- ✓ RoHS & Reach Compliant

- ✓ One-stop-shop for all metal surface finishing needs

- ✓ Decades of experience

- Learn more

Common Applications of Stainless Steel Pickling

1. Automotive industry

In the automotive industry, stainless steel pickling is crucial for maintaining the performance and longevity of automotive components. Stainless steel is commonly used in exhaust systems, mufflers, and other parts that are exposed to high temperatures and corrosive gases. By pickling these components, any impurities and oxides that accumulate over time can be effectively removed, ensuring optimal performance and preventing premature failure.

2. Food and beverage industry

Stainless steel is the material of choice in the food and beverage industry due to its hygienic properties and resistance to corrosion. However, during the manufacturing process, stainless steel equipment can accumulate contaminants that may compromise the safety and quality of food products. Stainless steel pickling is employed to remove any impurities, such as rust, scale, or organic residues, ensuring that food processing equipment remains clean and free from potential sources of contamination.

3. Pharmaceutical industry

Pharmaceutical companies rely on stainless steel pickling to maintain the cleanliness and sterility of their equipment. Stainless steel vessels, tanks, and piping systems used in the production of medications can harbor microorganisms or contain residual substances from previous processes. Pickling effectively removes these contaminants, ensuring that pharmaceutical products are free from any impurities that could compromise their quality or pose a risk to patients’ health.

4. Construction industry

Stainless steel is widely used in the construction industry for its strength, durability, and resistance to corrosion. From structural components to architectural elements, stainless steel adds both functionality and aesthetic appeal to buildings. However, during the fabrication and installation process, stainless steel can develop oxides, weld scale, and other surface contaminants. Pickling is employed to clean and restore the surface of stainless steel, eliminating any impurities and ensuring that the material retains its integrity and appearance.